Detailed product description

Celsius Combi 23-25 kW solid fuel plate boiler

Recommended fuels:

- Non-woody biomass

- Pellet biomass

Boiler accessories:

- Boiler thermometer

- Filling and draining tap

- Fire grates

Additional accessories available for purchase:

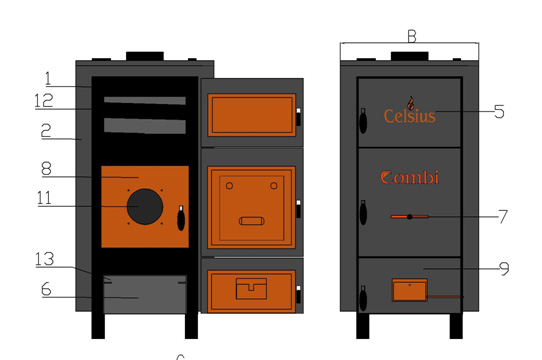

The boilers are suitable for burning non-woody biomass and wood pellets in automatic mode. Thanks to the special design, outstanding efficiency can be achieved with both fuels. The system can be assembled easily and quickly. In the case of mixed combustion, the large combustion door can be utilized. The wide cleaning door makes cleaning the boiler more comfortable. The 5 cm thick insulation and the multi-layer steel door contribute to higher efficiency.

|

Type

|

Celsius Combi 23-25

|

|

CELSIUS

|

|

|

Maximum power (kW) Mixed/Pellet

|

25/26

|

|

Fire door size (mm)

|

310*330

|

|

Heatable air space depending on the heating system (m 3 )

|

300-500

|

|

Efficiency ( %) Mixed/Pellet

|

83/91

|

|

Heating water connection (”) (1/l, 1/J)

|

2

|

|

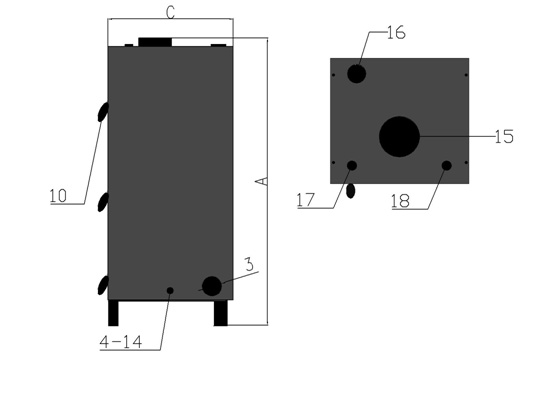

Flue connection (mm) (1/K)

|

132

|

|

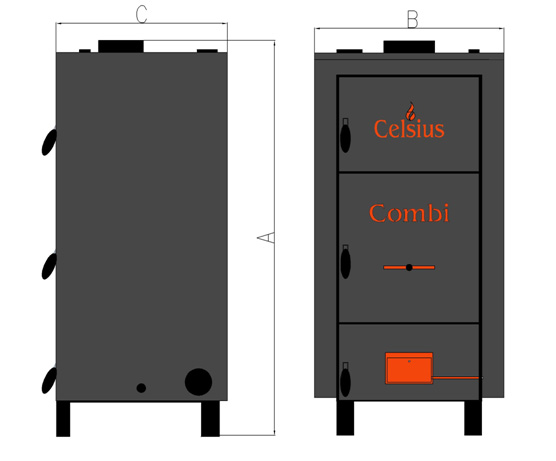

Height (mm) (A)

|

1125

|

|

Width (mm) (B)

|

555

|

|

Depth (mm) (C)

|

505

|

|

Weight (Kg)

|

174

|

|

Water volume (l)

|

65

|

|

Operating pressure (bar)

|

2

|

|

Operating temperature (°C)

|

90

|

|

Test pressure (bar)

|

3.8 - 4

|

|

Flue gas mass flow (g/s)

|

28

|

|

Firebox size (mm ) ( height*width*depth)

|

520*330*340

|

Celsius Safety Heat Exchanger

The peculiarity of wood burning is that the momentary intensity of thermal energy production is less controllable than, for example, in the case of pellet firing. This is because the amount of fuel in the firebox or its energy content is higher than the current heat demand of the building, so we must always ensure boiler overheating protection. One of the simplest solutions for this is to build an external safety heat exchanger into the system.

The Celsius Safety Heat Exchanger can be used with boiler outputs up to 56 kW. In the case of higher outputs, individual design and construction are required to protect the boilers from overheating.

How it works: If the temperature of the heating water in the tank connected to the boiler's heating outlet reaches or exceeds 98°C, a thermostatic valve opens, and the cold network water flowing through the heat exchanger located in the tank cools the heating water.

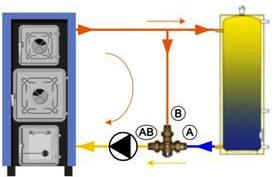

Celsius F boiler protection unit package 65 kW

Boiler protection unit to avoid condensation

Condensation is a phenomenon often experienced during the operation of solid fuel boilers, which in all cases results in boiler damage, a reduction in service life and efficiency, and additional heating costs.

Unwanted condensation can be avoided by using these units!

Advantages:

- Complete: the units are available assembled or in a complete package

- Space-saving: thanks to the compact design, they require minimal space

- The material is hot-forged brass

- Max. operating pressure: 10 bar

- Max. temperature: 100°C

- Selectable opening temperatures: 45, 55, 60°C

- A-AB Kvs value: 7.2

- B-AB Kvs value: 4.8

- Nominal opening temperature: +10K (set)

- Max. output (Δt 20K and 1400 l/h): 65 kW

- Max. Δp built into the return branch: 100 kPa

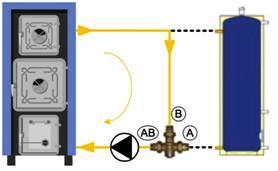

Operating Principle:

- Start-up Mode (Boiler Preheating): The "forward" heating water leaving the boiler is redirected to the "return" branch of the boiler until it reaches the opening temperature of the built-in thermostatic valve. The "A" branch of the valve is closed.

Buffer Tank Heating Mode: When the recirculated heating water temperature reaches the opening temperature of the thermostatic valve, the valve mixes the low-temperature heating water from the buffer tank with a part of the higher-temperature "forward" water, ensuring that the temperature returning to the boiler is not lower than the valve opening temperature, thus protecting the boiler from unwanted condensation. It allows excess heat energy, beyond what is used for mixing, to heat the buffer tank.

Buffer Tank Heating Mode: When the recirculated heating water temperature reaches the opening temperature of the thermostatic valve, the valve mixes the low-temperature heating water from the buffer tank with a part of the higher-temperature "forward" water, ensuring that the temperature returning to the boiler is not lower than the valve opening temperature, thus protecting the boiler from unwanted condensation. It allows excess heat energy, beyond what is used for mixing, to heat the buffer tank. Full Capacity Buffer Heating Mode: If the temperature of the heating water returning from the buffer reaches or exceeds the opening temperature of the thermostatic valve, the valve switches to a fully open state, allowing the buffer tank to be heated at full capacity. The "B" branch of the valve is closed. This condition is achieved when the valve opening temperature is exceeded by +10 K.

Full Capacity Buffer Heating Mode: If the temperature of the heating water returning from the buffer reaches or exceeds the opening temperature of the thermostatic valve, the valve switches to a fully open state, allowing the buffer tank to be heated at full capacity. The "B" branch of the valve is closed. This condition is achieved when the valve opening temperature is exceeded by +10 K.

For example, if the valve opening temperature is 55°C, then at +65°C it is fully open in direction A → AB.

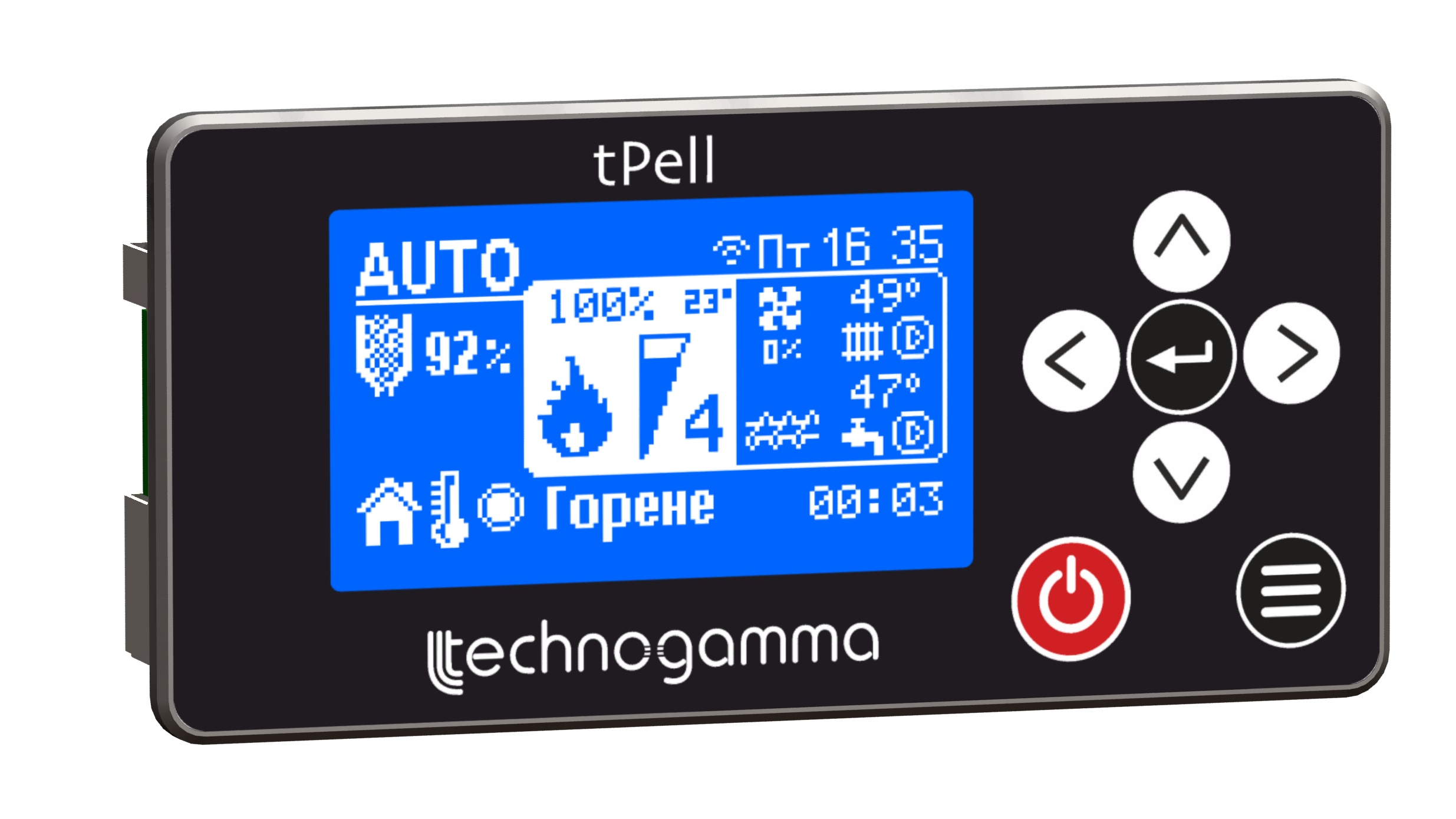

tPell Touch control

The tPell controller is the central part of every pellet facility. It ensures both the safe operation of the combustion process and the needs of the entire heating system. The modern design and compact housing provide a perfect finish for any modern pellet appliance!

The main principles of the device's design are ease of use, practicality, and accessibility, thereby providing the user with a sense of peace and security for their heating system. The modern device uses the latest generation technologies and components and offers the user:

- Intuitive and simple handling

- Operation via the Internet

- Unique design - panel with touchscreen capacitive buttons

Particular attention is paid to the convenience of system setup by installers, as well as to monitoring its performance:

- Flexibility and intuitiveness by setting all parameters of process management

- Economical operation thanks to the implemented modern Fuzzy Logic power modulation algorithm, which ensures that the set temperature is quickly reached and maintained

- Complete history of errors, events, and user actions

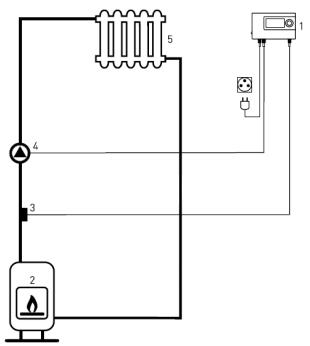

Connection diagram:

Connection diagram:

- tPell Touch control

- Heater

- Temperature sensor

- Circulation pump

- Heater

Celsius pellet burning equipment

The high-quality OXI burner ensures the most optimal performance!

Thanks to its WiFi-connected controller, it can be easily operated from a mobile application!

The self-cleaning head does the dirty work, so it does not require constant attention (also environmentally friendly).

Due to its user-friendly design, you can easily install and remove it from your boiler in seconds!

It also works perfectly with lower-quality pellets!

Maximum safety and minimum maintenance!

The OXI burners can also be purchased in a system package, so you can easily and conveniently ensure the warmth of your home!

Our burners with different performance levels are compatible with our boilers!

The weight of the product is 50 kg.

You can find out more about the Oxi ECO 20C pellet burner here .