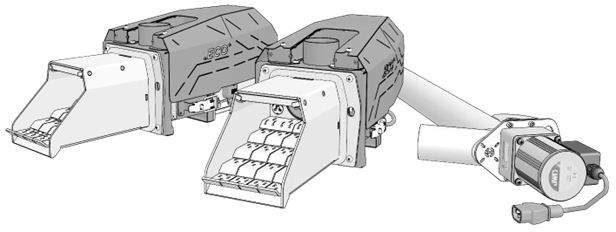

ECO 20C Pellet Burner

The ECO 20C pellet burner belongs to the ECO series designed for burning solid fuel in the form of pellet granules, with varying levels of contamination and granule sizes.

The burner operates in automatic mode, thus requiring no continuous supervision or personnel presence.

The movable grates of the OXI burner prevent slag from forming on the walls of the combustion chamber during pellet combustion. A ceramic coating built into the furnace significantly enhances the combustion of high-quality fuel and agricultural pellets. The stable combustion is ensured by the even distribution of primary air under the grate.

The burner is designed to operate in central heating boilers using solid fuel, as well as certain gas boiler models that allow for cleaning of the boiler heat exchanger.

The burner is an eco-friendly device that does not disrupt the ecological balance of the planet. The Celsius OXI Eco 20C pellet burner is environmentally friendly because it uses wood-based pellet fuel, which is a renewable energy source. Pellets have low moisture and ash content, reducing air pollution during combustion. The high efficiency of combustion results in less fuel consumption, further reducing environmental impact. The automatic control system of the burner head optimizes combustion, minimizing emissions.

The burner is controlled by a controller responsible for setting optimal operating parameters, such as fuel feed rate, regulation of air intake for combustion, flame color, boiler chamber temperature, and other settings. The burner controller is specifically designed to manage systems including solid fuel pellet boilers and basic automated heating systems like the heat regulation chamber. Additionally, the burner controller includes boiler and DHW temperature sensors.

Thanks to its Wi-Fi connected controller, the burner can be easily operated via a mobile application!

Pellet granule feeding is provided by an auger from a special container, continuously or intermittently feeding pellets to the burner head where they are burned, ensuring continuous boiler operation and adequate heat supply. It is important to regularly refill the pellet container when the fuel level is low to maintain continuous heating or hot water supply. This container can be purchased separately.

Using high-quality pellets ensures maximum efficiency of the burner.

|

Parameters

|

Value

|

|

Diameter

|

6 – 8 ± 1, mm

|

|

Length

|

6 – 60, mm

|

|

Bulk density

|

650 ± 200 kg/m3

|

|

Moisture content

|

≤ 10%

|

|

Ash content

|

≤ 5%

|

|

Readiness

|

≤ 3%

|

Technical Specifications of the Burner

! The nominal power of the burner head has been determined using pellets that comply with the ENplus standard. If pellets with different calorific values, ash content, or moisture content are used, the nominal power of the burner head will vary.

|

Parameters

|

Modell E.125

|

|

Nominal power, kW

|

20

|

|

Minimal power, kW

|

4

|

|

Power supply, V/Hz

|

230/50

|

|

Average consumer power, W

|

40

|

|

Ignition power consumption, W

|

360

|

|

Total length, mm

|

547

|

|

Total heigt, mm (without elbow)

|

212

|

|

Total width, mm

|

202

|

|

Furnace height, mm

|

125

|

|

Furnace width, mm

|

125

|

|

Complete combustion

|

>98%

|

|

Achievable boiler efficiency

|

<92%

|

|

Smooth power modulation

|

Igen

|

|

Fuel spiral included

|

Igen (Ø70mm)

|

|

Meltable corrugated hose included

|

Igen (1mm)

|

|

Peak pressure in the boiler, Pa

|

20

|

|

Weight of the EVO burner, kg

|

12,5

|

|

Weight of fuel spiral conveyor (1.5 m)

|

8,8|

|

You can download the complete technical description of the ECO 20C pellet burner from here.

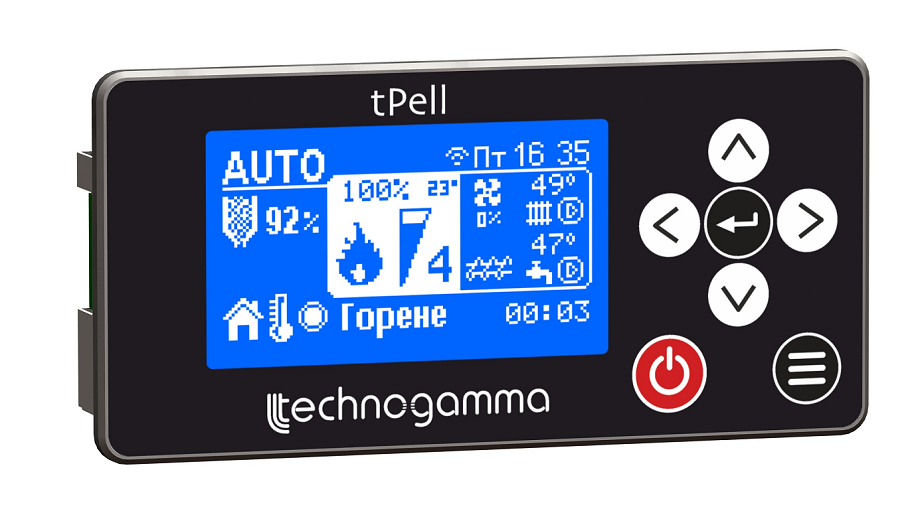

tPell

Pellet Burner Controller

The tPell Pellet Burner Controller is a specialized device used for controlling and optimizing the combustion process in pellet boilers. These modern, digital control units enable automated operation and more efficient energy use of pellet boilers.

- Combustion Process Optimization: tPell controllers precisely regulate the pellet combustion process within the boiler, ensuring complete and efficient burning of the pellets. This minimizes the amount of unburned material and harmful emissions. Optimal combustion contributes to both a cleaner environment and higher heat production.

- Automated Operation: The controllers automatically adjust the pellet feed and combustion in the boiler, taking into account external temperature, heating demands, and the available amount of pellets. This results in energy-efficient operation and convenience for the user, as it requires minimal intervention in the boiler's operation.

- User Interface: tPell controllers typically feature a modern, user-friendly interface that allows users to easily navigate settings, monitor the boiler's status, and intervene if necessary. The interface often includes error codes, which facilitate quick diagnosis and resolution of problems.

- Timed Operation: Many tPell controllers offer timed operation, helping to optimize the boiler's performance according to weather changes and the habits of the household residents. For example, the boiler can be pre-set to operate at higher or lower temperatures at specific times, thereby saving energy.

- Alerts and Error Notifications: The controllers monitor the boiler's operation and issue alerts or error notifications if any issues arise, such as low pellet levels or combustion errors. This allows for prompt intervention and maintenance of uninterrupted boiler operation.

Overall, tPell Pellet Burner Controllers not only optimize the operation of pellet boilers but also significantly enhance user comfort and safety. Through automated and intelligent control, they improve energy efficiency and reduce environmental impacts, making them a key element of sustainable heating solutions.

Technical Specifications

- Supply Voltage: 230 V, 50 Hz

- Controller Power Consumption: 3.6 VA

- Total Output Current: 6.3 A

- Operating Temperature: 0 ... 40 °C

- Protection Level: IP 20

- Dimensions: 138 x 67 x 52 mm

- Display: LCD 128 x 64 px

- Pt1000 Temperature Sensor: -40 ... 250 °C

- NTC Temperature Sensor: -40 ... 125 °C

You can download the complete technical description of the tPell Pellet Burner Controller from here.