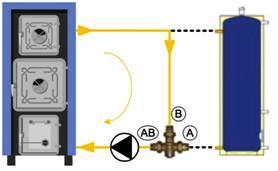

Principle of operation:

1. Starting the system (heating the boiler)

After the launching of the boiler, the thermic valve is fully closed towards the user (gate A) and remains in this condition until the fluid is warmed up by the heating source, gets the opening temperature of the thermic valve (corresponding to the calibration value, f.i. 55°C). During this step the fluid sent by the boiler fully recycles through the by-pass (gate B) so the boiler temperature rises very quickly.

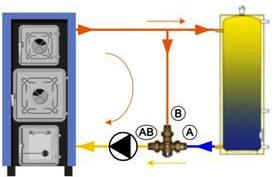

2. Loading the system (heating the tank)

Reaching the opening temperature (f.i. 55C), gate A proportionally starts to open while gate B proportionally starts to close. The boiler temperature slowly rises, giving energy to the end user, but the returning temperature will not decrease below the calibrated temperature (f.i. 55°C).

3. System operation

Starting from point 2, the flow temperature progressively increases to fully open gate valve A. This will correspondingly close gate valve B. This happens at approximately circa 10k higher than the calibration or opening temperature (therefore in this example at 65c). Now the installation is fully operational the supply fluid temperature can increase to set value.

For example, if the valve opening temperature is 55°C, then it is totally opened in the direction of A → AB in case of +10°C.